Everyone knows that a good LED screen comes from a good LED display factory. LED displays have become an essential part of our modern world, providing vivid, high-quality visual displays for a variety of purposes. From advertising to entertainment, LED displays have taken over traditional displays in many industries.

Behind every LED display, there is a factory working tirelessly to produce it. In this blog, we'll take a look at what goes on behind the scenes in a day in the life of an LED display factory.

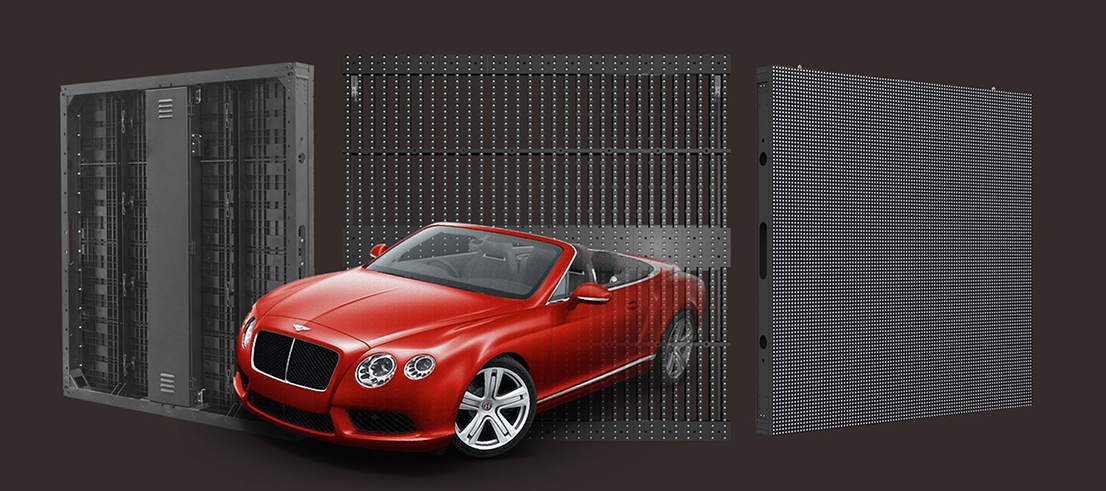

LED display factories are responsible for the production of a wide range of LED displays, including indoor and outdoor displays, digital billboards, and LED video walls. These factories are equipped with advanced manufacturing facilities and highly skilled workers who specialize in various stages of the production process.

The production of LED displays involves several steps, including design, prototyping, sourcing of materials and components, production, assembly, quality control, testing, and packaging. Each stage requires specific skills and equipment to ensure the highest quality of the finished product.

Here I would like to introduce to you an LED display factory with many years of manufacturing experience and a lot of achievements through its own efforts: Kingaurora.

Now that we have a basic understanding of the production process, let's take a closer look at a day in the life of Kingaurora's LED display factory.

The day in an LED display factory typically begins early in the morning. The factory workers arrive and start their day by reviewing the production schedule and preparing the production lines for the day's work.

Production begins, and the factory workers start the assembly process. The LED modules and other components are assembled onto the display's frame, and the display starts to take shape.

The design stage is where the concept for an LED display is created. The design team creates a blueprint for the display based on the client's requirements, taking into consideration factors such as display size, resolution, and color accuracy. Once the design is finalized, a prototype is created to test the functionality and visual quality of the display.

After several hours of assembly, the displays move to the quality control stage. The quality control team inspects each display carefully, looking for any defects or imperfections that need to be addressed.

After the lunch break, the displays move to the testing stage. The displays are tested for brightness, color accuracy, and viewing angle, among other factors. The testing team ensures that every display meets the client's requirements.

Once the displays pass the testing stage, they are ready for packaging and shipping. The factory workers use high-quality packaging materials to protect the displays during shipping.

The day comes to an end, and the factory workers wrap up their work for the day. They review the production schedule for the next day and prepare the production lines for the following day's work.

As a reliable LED display factory, Kingaurora has been developing more beautiful, energy-saving, and efficient lamps for many years. Their 3-in-1 full-color DIP lamp is a patented product with better color consistency, which can present a better image experience.

Moreover, its brightness is as high as 8000 nits, and its avg power is 147W/m2. This makes it energy efficient up to 50%!

Let me introduce their hot selling products: B0808 Pro display in Outdoor Mesh Screen Aurora Beam Bpro Series

Kingaurora's Outdoor Fixed Screen Mesh Screen B0808 Pro has a solid or transparent option, making it suitable for a variety of applications such as storefronts, transportation hubs, and outdoor advertising. Its unique air convection design also reduces the need for air conditioning, making it an energy-efficient option.

The display's sleek aluminum frame and thin design make it an aesthetically pleasing option. With its simple and beautiful design, it can easily blend into any outdoor environment and add a touch of modernity to the space.

With a brightness of 8000nits, Kingaurora's Outdoor Fixed Screen Mesh Screen B0808 Pro delivers a clear and vivid image, even in direct sunlight. This feature ensures that the display can effectively deliver messages or advertisements to the audience, making it a high-visibility option for outdoor applications.

LED displays have become an integral part of our modern world, providing vivid, high-quality visual displays for a variety of purposes. As the demand for LED displays continues to grow, Kingaurora is expanding its operations to meet the demand.

Kingaurora's LED display factory is investing in advanced manufacturing facilities and technologies to increase production efficiency and reduce production costs. The factories are also exploring new applications for LED displays, such as virtual and augmented reality.

The future of LED display factories is bright, with new technologies and applications driving growth and innovation.

In conclusion, LED display factories play a crucial role in the production of high-quality visual displays that have become an essential part of our modern world. Behind the scenes, skilled workers use advanced manufacturing facilities and technologies to produce LED displays that meet the highest quality standards.

The future of LED display factories is bright, with new technologies and applications driving growth and innovation. Kingaurora's LED display factories will continue to play a crucial role in bringing cutting-edge visual displays to life, helping businesses and organizations connect with their audiences in new and exciting ways.

3th Building,Gaosite Zone Pingshan

New District, Shenzhen

sevice88@kingaurora.com

3th Building,Gaosite Zone Pingshan

New District, Shenzhen